Besides being an aesthetic upgrade, custom alloy wheels transform your car’s performance. Whether you want a lower weight, better handling, or a unique style, alloy wheels offer a blend of functionality and flair that factory-fit steel wheels simply can’t match. But what goes into making these high-performance wheels? In this blog, we’ll tell you about the complete process of how custom alloy wheels are made. Understanding how aftermarket wheels are made will help you appreciate the craftsmanship and guide you if you’re planning to buy custom wheels in Dubai.

Why Are Alloy Wheels Popular in Dubai?

Alloy wheels are wheels made from a blend of metals, usually aluminium or magnesium. They are lightweight, yet strong. They also boast of better heat dissipation. Most custom alloy wheels also look better than factory-fit alloy wheels and steel wheels.

Automobile enthusiasts in Dubai value both performance and luxury. Custom alloy wheels are popular here as they reduce the weight of a car, and so give faster acceleration and superior handling.

Custom alloy wheels and factory-fit alloy wheels also come in more intricate designs. This wide variety makes aftermarket alloy wheels a top choice for car enthusiasts in Dubai.

Also, the heat dissipation properties of alloy wheels help maintain brake performance in the extreme temperatures of Dubai. This makes them a good choice for those who engage in high-performance driving or off-road adventures in the UAE’s race tracks and deserts.

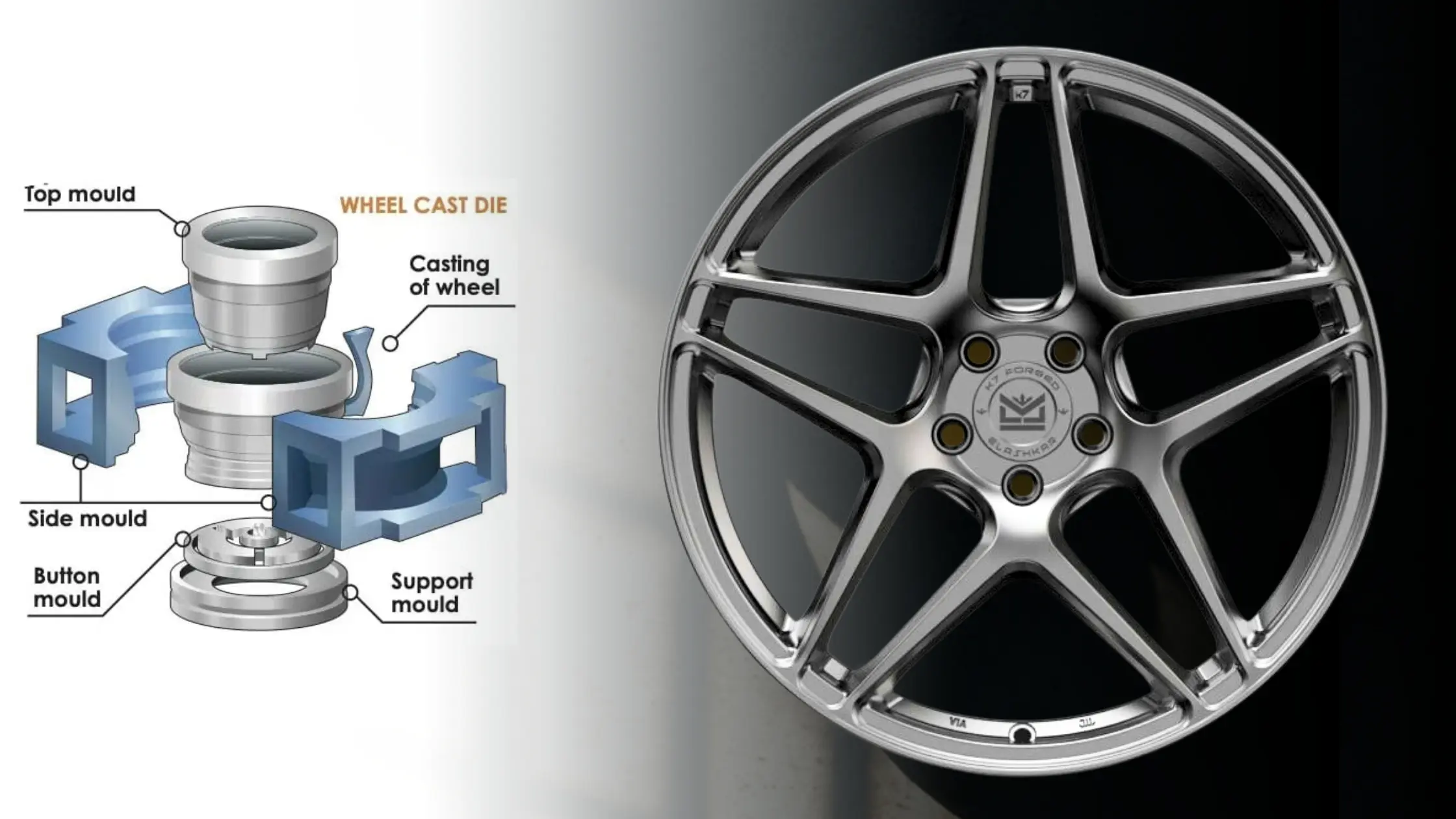

The Manufacturing Process of Custom Alloy Wheels

Step 1: Designing the Wheel

Engineers and designers of the best wheel manufacturers, use advanced CAD (Computer-Aided Design) software to create blueprints that balance good design, performance, and structural integrity. They also consider factors like aerodynamics, weight distribution, and the intended use, be it for street, track, or off-road.

Step 2: Material Selection

Most aftermarket wheels are made from aluminium or magnesium alloys. High-quality materials help the wheels withstand the stresses of everyday driving as well as the race track or off-road conditions. K7 Forged uses state-of-the-art aerospace-grade aluminium 6061-T6 for manufacturing the best custom alloy wheels in Dubai – be it for drag racing wheels, track racing wheels, off road forged wheels or beadlock wheels.

Step 3: Forging the Wheel

Forging involves compressing a solid piece of aluminium alloy under extreme pressure. This process aligns the aluminium’s grain structure, and the wheel that comes out is both stronger and lighter. Forged wheels are highly regarded in Dubai’s automotive world for their exceptional performance in racing and off-roading.

Step 4: Machining and Finishing

For the wheel to meet standards, high-precision CNC (Computer Numerical Control) machines are utilized for cutting, drilling, and smoothing. This step balances and makes it meet the precise tolerances needed for high-performance applications. The machining process also allows for customization. You can have unique spoke designs or patterns on your custom wheels.

Step 5: Heat Treatment and Strengthening

After machining, the wheels then head over to heat treatment to increase their strength and durability. Here, the wheels are heated to a high temperature and then rapidly cooled. This makes the wheels more resistant to cracking and deformation.

Step 6: Surface Finishing and Coating

Finally, the wheels are polished, painted, powder-coated, or anodized. If you choose to go with K7 Forged for custom alloy wheels, you’ll get an endless collection of premium coatings and finishes. Our surface finishing also adds a layer of protection against corrosion, wear, and environmental damage. K7 Forged customization options are virtually limitless, so you can choose from a variety of colours, textures, and finishes that match your car.

Quality Control for Custom Alloy Wheels

Custom alloy wheels must go through a series of tests to ensure that they can endure high-performance driving. This implies you won’t have to worry if you want to switch from factory wheels to aftermarket wheels.

K7 Forded wheels undergo x-ray inspections to detect any internal flaws or voids. Impact testing assesses how well the wheel can absorb shocks without cracking or deforming. Our rigorous fatigue testing simulates the long-term stresses wheels endure. These rigorous tests give K7 Forged the confidence to provide you lifetime structural warranty on all our custom wheels.

Certifications and Standards

In Dubai, alloy wheels must meet stringent criteria established by local and international regulatory organizations. The GCC Standardization Organization (GSO) establishes criteria for alloy wheel manufacturers to follow, guaranteeing that their products are safe and trustworthy for usage in the Gulf area. Wheels that meet these criteria are frequently stamped with certificates such as ISO 9001.

Adherence to these standards helps a wheel rim manufacturer like K7 Forged to maintain our reputation among the best wheel manufacturers of custom alloy wheels in Dubai.

The Final Product – Custom Alloy Forged Wheels

After passing quality control, the wheels get their final surface treatments. This may include polishing, painting, powder coating, or anodizing. In Dubai’s hot and sandy climate, a robust coating helps prevent the wheels from corrosion and wear. These finishes also allow for customisation, so you may match your wheels to the appearance of your car.

Once finished, the wheels are distributed to K7 Forged customers across Dubai and UAE. Once you place an online order with K7 Forged, your wheels reach your doorstep in just 3 weeks.

Order Custom Alloy Wheels Online with K7 Forged

Custom alloy wheels may dramatically improve a vehicle’s performance and handling. From precise design and material selection to thorough production and severe quality control, every step is taken to produce wheels that match the highest standards.

Whether you’re driving through Dubai’s city streets or taking on the trials of off-road terrain, the perfect set of custom alloy wheels may make all the difference. Investing in quality wheels crafted through this meticulous process ensures not only an improved aesthetic but also driving dynamics suited to Dubai’s demanding conditions.

Visit our website to find a set of premium aftermarket wheels that you like.