While most people consider custom wheels an aesthetic choice, car enthusiasts like you understand how crucial wheels are to your car’s performance, handling, and braking.

That said, not all wheels have the same benefits. It depends on what you want from your car. In this blog post, we’ll have a head-to-head battle between two of the most popular forged wheels for car enthusiasts – monoblock and two-piece forged.

We’ll discuss how they’re manufactured, the strengths and weaknesses of each technology, and finally we’ll determine the winner. So, buckle up!

Understanding Forged Wheels: Strength Redefined

Before we jump into the heart of the matter with Monoblock and Rotary Forged wheels, let’s take a moment to appreciate the sheer genius of forged wheels.

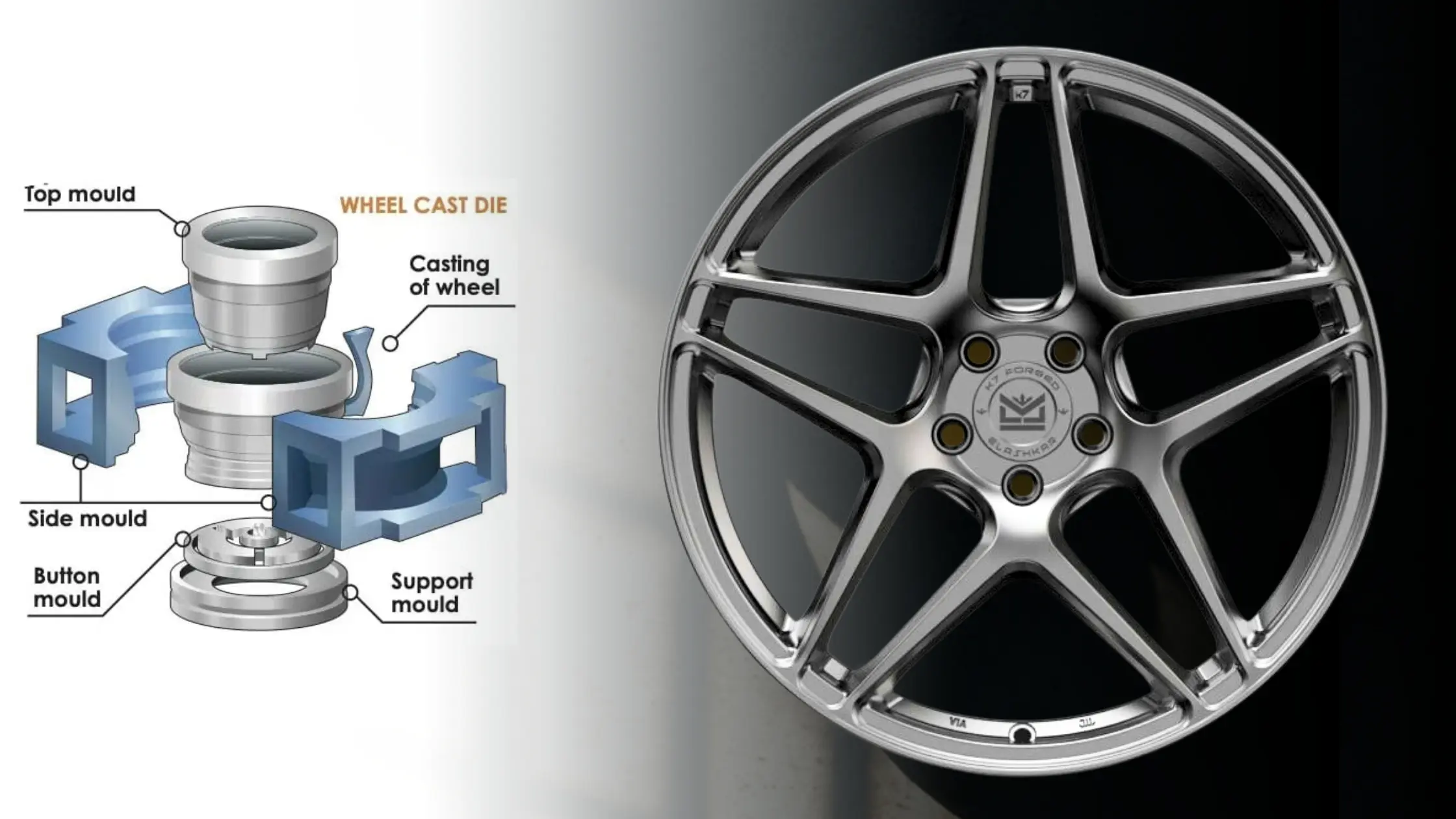

Unlike traditional cast wheels, which are made by pouring metal into moulds, which is fine for your everyday ride but might not stand up to the rigours of real driving gusto, forged wheels are a different breed altogether, crafted for those who don’t just drive, but drive with purpose.

It all starts with a chunk of top-notch aluminium alloy, getting cosy in the heat until it’s ready to be shaped. Then comes the fun part: a hydraulic press that would make even the Hulk envious, slams down with a force that sculpts this metal into a wheel that’s not just a wheel, but a statement.

This isn’t just about brute force, though. This process is like a metamorphosis for the metal, squashing out any imperfections and leaving you with a wheel that’s denser, tougher, and ready to take on the world. Here are the benefits:

Superior Strength:

Forged wheels have a much higher strength-to-weight ratio when compared to cast wheels. They can take on greater impact forces without bending or cracking. This makes handling them a breeze, especially in performance driving.

Reduced Weight:

Forged wheels are surprisingly lightweight considering their brute strength. This is because the forging process removes unnecessary material while maintaining structural integrity. Meaning, you’ll get improved acceleration, handling and responsiveness.

Enhanced Durability:

The higher density of forged wheels makes them more resistant to wear and tear from even the harshest driving conditions. With less susceptibility to warping or cracking you’re guaranteed to get long-lasting performance.

Now that we know what makes forged wheels so special, let’s take a look at monoblock forged wheels and two-piece forged wheels.

Deep Dive: Monoblock Forged Wheels – The Stalwart Champion

Monoblock Forged Wheels, also known as one-piece forged wheels, are the traditional powerhouse in the world of high-performance wheels.

Their forging process is more or less the same as the one mentioned earlier. The entire wheel, from the centre barrel to the spokes and rim, comes from a single block of aluminium alloy. With zero seams, this creates an incredibly robust structure.

Advantages of Monoblock Forged Wheels

- Unmatched Strength:

The single-piece construction gives monoblock wheels ultimate strength and rigidity to handle extreme loads and stresses. This makes them ideal for high-performance applications like racing and track days.

- Durability You Can Trust:

Forged aluminium with this dense grain structure is naturally resistant to wear and tear. Monoblock wheels can endure years of punishment on the road without compromising performance.

- Classic Design Aesthetics:

For those who like vintage timeless and elegant designs, monoblock is the way to go. The clean lines and seamless construction make way for a sophisticated look that compliments a variety of car styles.

Drawbacks to Consider

- Weight Matters:

Monoblock wheels are lighter than traditional cast wheels. But they are slightly heavier than Two-piece forged wheels, due to the use of more metal.

- Design Limitations:

The single-piece construction limits the design options to some extent. Complex spoke patterns or intricate details are difficult to include in monoblock wheels when compared to two-piece forged wheels.

Deep Dive: Two-piece Forged Wheels – The Lightweight Challenger

Two-piece Forged wheels are a compelling alternative to monoblock wheels. What makes them special is their unique two-step forging process:

The Forging Finesse:

Two-piece forged wheels start similarly to monoblock, with a heated aluminium billet. But instead of forging the entire wheel at once, the process created two distinct pieces:

- Center Barrel:

The same intense pressure forging technique creates this section. The heart of the wheel is therefore robust and structurally sound.

- Rim Section:

A spinning mould with rollers presses against the heated aluminium, shaping it into a lightweight and more flexible rim design.

Advantages of Two-piece Forged Wheels

- Superior Strength-to-Weight Ratio:

Two-piece forging achieves a balance between raw strength and weight reduction. The robust centre barrel ensures excellent structural integrity, while the lighter rim makes the entire wheel lighter when compared to a monoblock. This means improved acceleration, handling and maybe better fuel efficiency.

- Wider Design Flexibility:

Forming the rims separately allows for more intricate spoke patterns and unique design elements. This makes Two-piece forged wheels perfect for those who want a balance between performance and aesthetics.

- Cost Considerations:

Two-piece forged wheels fall between cast and Monoblock wheels when it comes to price. So they’re a cost-effective option for those who seek a performance upgrade without breaking the bank.

- Potential Drawbacks

While incredibly strong, Two-piece forged wheels do not quite match the absolute raw strength of Monoblock wheels. However, for most normal performance-driving, the difference is usually not visible.

Monoblock vs. Two-piece Forged: A Head-to-Head Comparison

| Feature | Monoblock Forged Wheels | Two-piece Forged Wheels |

| Strength | Highest | Excellent |

| Weight | Moderate | Lighter |

| Design Options | Limited | More Flexible |

| Durability | Exceptional | Excellent |

| Performance Benefits | Ideal for high-performance driving, superior handling | Excellent balance of performance and weight reduction |

| Cost | Highest | Moderate |

The Verdict: It Depends on Your Needs

Choosing an outright winner in this comparison is difficult because it depends on your driving style. Here’s our recommendation:

For hardcore performance enthusiasts and racers: Monoblock wheels may suit to better owing to their unmatched strength and handling.

For drivers seeking a balance of performance, weight reduction, and design freedom: Two-piece Forged wheels offer a compelling option at a more accessible price point.

No matter what you choose, both Monoblock and Two-piece Forged wheels are a significant upgrade over traditional cast wheels and alloy wheels.

If you’re in the market for superior forged wheels in the UAE, then check out our diverse collection. Always remember to choose the best forged wheels manufacturer for reliable performance.